Customizing your own dog collars may sound simple—until you actually start. If you’re building a brand, especially for the first time, you’ll need to make decisions across materials, sizes, logo options, MOQ, packaging, and more. This guide walks you through the full process from a brand owner’s perspective, focusing on what you need to do, what to consider, and what to avoid.

Step 1: What Do I Want My Product to Express?

Before asking for a quote, ask yourself:

- Who are my customers? Budget or premium buyers?

- Should this product be functional, aesthetic, or both?

- Do I want it to match other accessories (leash, harness)?

- What pricing range do I need to hit?

Tip: Clarity at this stage helps avoid delays or constant back-and-forth later.

Step 2: Which Materials and Styles Make Sense for My Brand?

You don’t need to know everything, but you should have opinions. Consider:

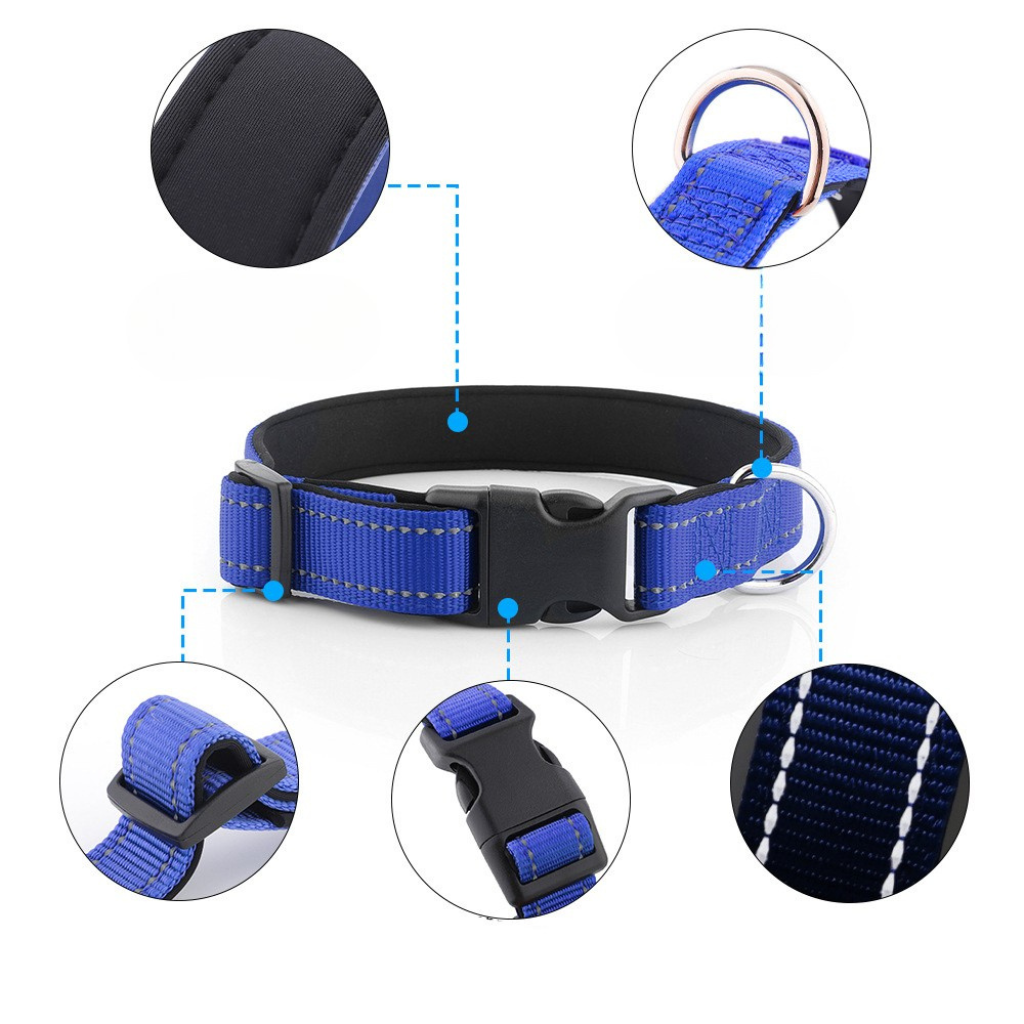

- Material: Nylon (durable), polyester (cheaper), neoprene (soft), leather (premium)

- Hardware: Plastic or metal? Do I care about weight or look?

- Features: Reflective? Waterproof? Breathable? Is that on-brand?

Common Mistake: Letting suppliers choose everything for you.

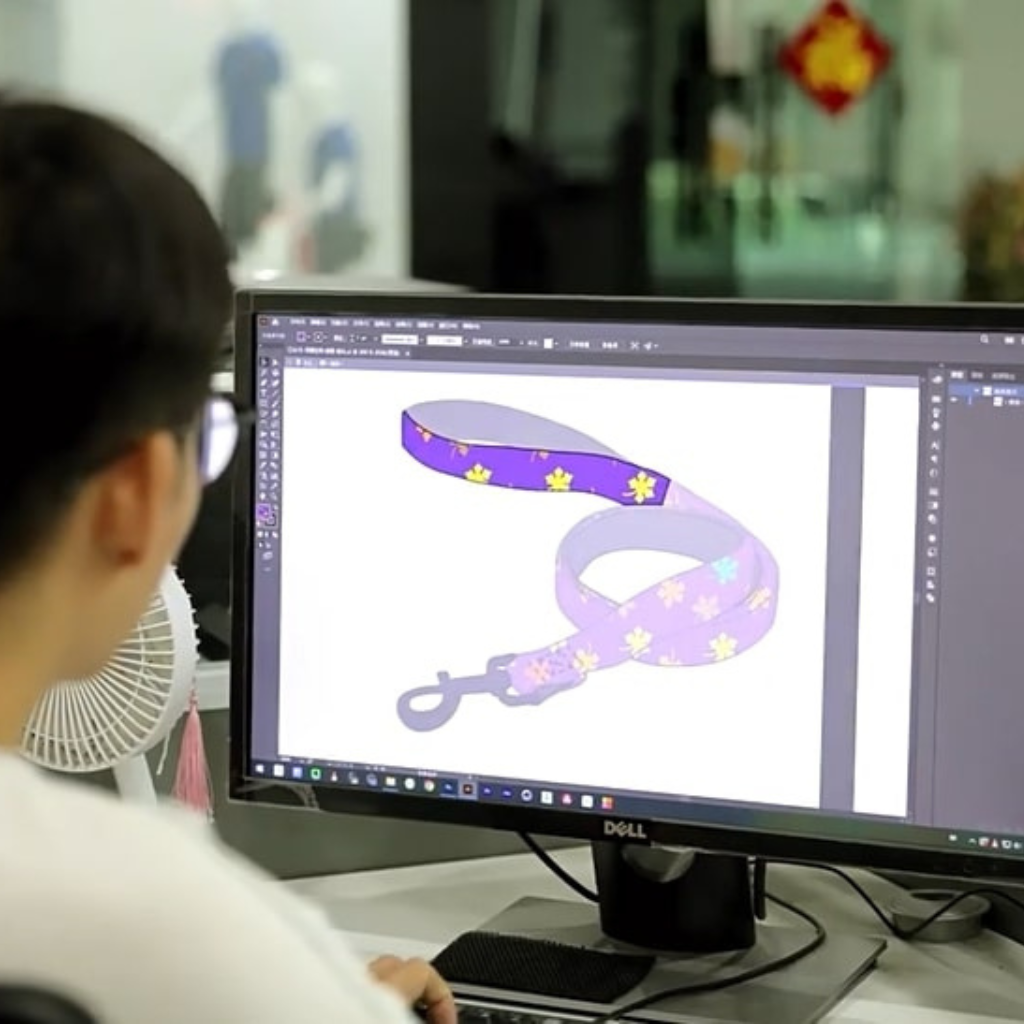

Better Approach: Ask for material photos, comparison samples, or product videos. Even a screenshot of what you like helps.

Step 3: How Should My Logo Be Applied?

You’ve got a logo—but how should it appear?

- Print directly on the collar? Or a rubber tag?

- Woven label? Laser on hardware?

- One-color or full-color?

- Do I want it obvious or subtle?

Decision point: This is about brand identity. Loud vs quiet? Casual vs premium?

Risk: Some methods fade fast, or don’t work well on certain materials. Ask for samples or at least real photos of similar cases.

Step 4: What’s the Right MOQ for Me?

Ask yourself honestly:

- Am I testing the market or scaling a working product?

- Can I sell 500pcs in 3 months? Or do I want 100pcs first?

- Do I prefer fewer styles with more quantity, or more styles with fewer pieces?

Reality check: Most factories do 100–300pcs per style as a starting point.

Smarter option: Start with 1–2 styles, moderate quantity. Expand once you get feedback.

Step 5: Do I Need a Sample? What Should I Check?

Short answer: yes. A sample helps you confirm:

- Material and stitching feel

- Size and fitting range

- Color accuracy (especially Pantone)

- Logo execution

What to ask yourself:

- Does this reflect the product I want my brand to be known for?

- Would I be proud to ship this to an influencer?

Pro tip: Request video or high-resolution photos first if time is tight, but never skip physical sampling for first-time production.

Step 6: What Could Go Wrong in Production?

Even with the best planning, some areas often go off track:

- Color mismatch: Not confirming Pantone or fabric batch changes.

- Logo misplacement: Unclear design files or no digital proof before production.

- Hardware inconsistency: Different batches if not locked early.

- Wrong packing method: Damaged goods or messy unboxing.

What to do:

- Always request pre-production confirmation (photo/video or digital layout)

- Lock specs in writing

- Ask for sample photos from finished goods before shipment

Step 7: Have I Thought About Packaging and Labeling?

If you’re building a brand, don’t overlook this:

- Do I need individual polybags or retail boxes?

- Do I want barcodes, hang tags, or instruction cards?

- Is packaging consistent with my brand tone?

Packaging may not be the biggest cost, but it heavily affects perception.

Step 8: After Delivery—What Do I Check First?

Once your goods arrive:

- Count cartons and pieces

- Check 3–5 items from each box: logo, stitching, sizing

- Check one item under real-use conditions (pulling, soaking, etc.)

Ask yourself:

- Is this something I would reorder?

- Would my customers give this 5 stars?

If not: Note what’s off. Build it into your next order spec sheet. Every first order teaches something.

Summary: What You Need to Prepare as a Brand Owner

Here’s a checklist to keep you in control:

- A clear brand positioning and target customer

- A preferred material and style reference

- Your logo files (vector preferred) and branding direction

- Idea of MOQ and how much inventory you’re ready to hold

- Confirmation plan for sample → order → QC

- Thoughts on packaging and unboxing experience

- A mindset ready to test, learn, and adjust

You don’t need to be an expert—but you do need to ask the right questions.