From rugged outdoor leashes to printed fashion collars, the material used plays a central role in product durability, appearance, and functionality. But beyond just “nylon” or “leather,” each material comes in different grades, thicknesses, and coatings—each with its own strengths and trade-offs.

Let’s explore the most commonly used materials for dog collars and leads, and take a closer look at how different material specifications impact product use, pricing, and customization.

1. Nylon: Common, But Not All the Same

Nylon is a staple material in pet products, but within “nylon” there’s a wide range of qualities—mainly determined by denier rating, weave tightness, and surface texture.

Nylon D600 vs D1000: What’s the difference?

- D600 nylon is lighter, more flexible, and cheaper. It’s often used for entry-level leashes or small-dog collars. However, it may fray more easily and isn’t ideal for heavy pulling.

- D1000 offers higher tensile strength and better abrasion resistance. It feels denser and is commonly used in large-dog products or where durability is key.

Use Cases by Spec:

- D600 Nylon: Promotional items, small-breed leashes, basic collars

- D1000 Nylon: Adjustable harnesses, utility collars, export-ready stock

Printing & Logo Options:

- D600 and D1000 both support heat transfer printing and sewn-on woven labels.

- For durable branding, D1000 handles jacquard weaving better due to its tighter structure.

Market Insight:

Buyers often start with D600 for cost-sensitive markets, then upgrade to D1000 once durability complaints arise or when shifting to mid-range segments.

2. Polyester Webbing: Great for Printing, But Which Type?

Polyester is often used interchangeably with nylon, but its weave and coating define its performance.

- Plain polyester webbing is rigid and supports sublimation well, ideal for printed collars.

- Soft-touch polyester adds comfort and flexibility but may be less suitable for sharp image printing.

- Some manufacturers use polyester-cotton blends to reduce costs, but this sacrifices color vibrancy.

Spec Breakdown:

- Thickness: 1.0mm – 2.5mm; thicker webs support heavy-duty hardware

- Weave: Tight weaves give better printing clarity, loose weaves feel more breathable

Product Fit:

- Best for full-pattern printed collars and logo-driven leash designs

- Also ideal for matching sets where print continuity is important

Logo Execution:

Sublimation, screen printing, and full-wrap prints all work well on tight-weave polyester.

3. TPU/PVC Coated Webbing: One Material, Many Grades

TPU and PVC-coated webbing combine strength and waterproofing, but grades vary in coating thickness, flexibility, and gloss level.

Common Specs:

- 0.8mm coating: more flexible, lighter feel—used for regular pet collars

- 1.2mm+ coating: stiffer, stronger—used in working dog leashes or heavy-duty pull gear

- TPU vs PVC: TPU is more flexible and eco-friendlier but costlier. PVC is cheaper and tougher, but more plastic-feeling.

Use by Grade:

- Thin TPU: colorful waterproof leashes for retail

- Thick PVC: hunting dog gear, police dog leads

Hardware Matching:

Heavier grades are paired with stainless steel or brass hardware to maintain balance and durability.

Logo Strategy:

Screen printing or UV ink printing is common. Thicker surfaces support embossed branding.

Market Behavior:

Many brands start with TPU for aesthetics and then move to thick PVC when targeting outdoor/professional segments.

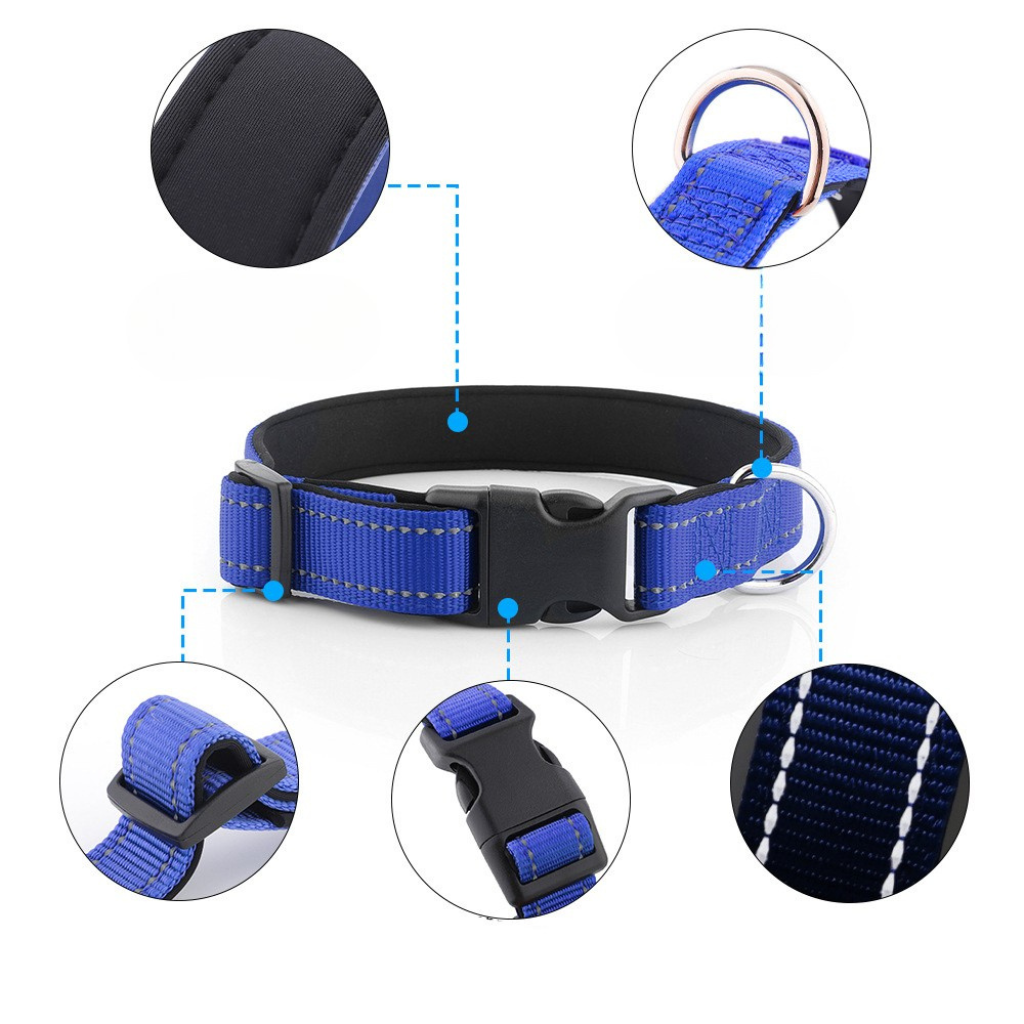

4. Oxford Fabric: Softshell, But Needs Support

Oxford is a woven fabric often laminated or backed by foam or mesh. It comes in denier grades (e.g., D210, D600, D1000) and coating types (PU, PVC).

Material Comparison:

- D210: ultra-light, mostly used in padded linings

- D600: good for decorative harness surfaces

- D1000: rugged enough to be exposed as outer shell

Performance Notes:

Oxford fabric alone lacks structural rigidity, so it’s mostly used as a cover on padded products. Its printability is good, especially when PU-coated.

Best Use Cases:

- Padded no-pull harnesses

- Decorative collars

- Lightweight leashes for small dogs

Branding Techniques:

Sublimation printing, heat transfer on flat surfaces, or stitched rubber tags.

5. Leather: Grades Define the Product Tier

Even within leather, there’s a difference between top-grain, genuine, and bonded leather.

- Top-grain leather: premium, long-lasting, ideal for handcrafted lines

- Genuine leather: more affordable, widely used in entry-level boutique collars

- Bonded leather: low-cost but less durable, mostly for aesthetic value

Finish Matters:

Matte finishes pair well with classic buckle hardware; glossy finishes appeal to fashion buyers.

Logo Applications:

Embossing, laser engraving, or embedded metal tags

A dog collar isn’t just fabric and metal—it’s a collection of deliberate material choices. Each grade, each weave, each coating has its place in the market. Choosing the right one depends on your goals:

- Are you targeting functional utility or fashion-first consumers?

- Are you building volume or value?

- Do you need to support high-tensile hardware, printing clarity, or waterproof features?

By understanding not just the material type but also its specification and context, you can create smarter, more targeted products—whether it’s for your retail line, wholesale orders, or OEM development.