A collar, leash or harness is never just a tool. It is a moving stage where your brand walks through the park, the street, or the beach. The logo that sits on it has to look right on day one and still hold its shape after months of rain, sunlight, and daily tugging. Choosing the right logo method isn’t only about decoration—it’s about how you want your brand to be seen every single day.

How Logo Choice Shapes Product Identity

Every logo technique has its own voice. A soft woven tab feels approachable and casual. An embossed mark pressed into PVC whispers premium quality without trying too hard. A bold silicone patch jumps out with energy and sportiness. A polished metal plate signals timeless heritage. When you decide how to apply your logo, you are not just selecting a technique—you are deciding what story the product tells on every walk.

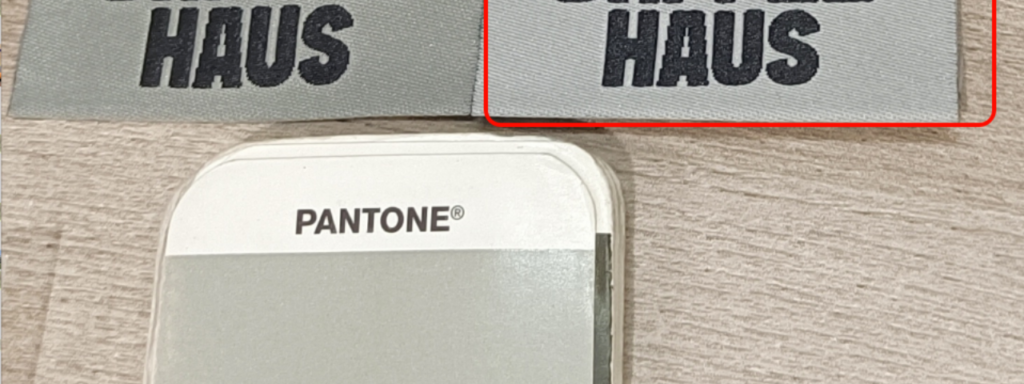

Materials and Techniques at a Glance

| Technique | Works best on | Visual feel | Durability in wet use | Typical brand style |

|---|---|---|---|---|

| Woven label | Nylon, polyester webbing, fabric harness panels | Clean and compact | Good | Everyday, casual, value focused |

| Embroidery | Fabric harness panels, padded collars | Textured and crafted | Very good on fabric | Heritage, craft, classic |

| Silicone or rubber patch | Nylon, polyester, PVC coated webbing, fabric panels | Bold and modern with depth | Excellent and waterproof | Outdoor, sport, performance |

| Emboss or deboss | PVC coated webbing, leather, faux leather | Subtle and premium | Excellent | Minimalist, luxury, refined |

| Heat transfer print | Nylon, polyester, fabric panels | Sharp color and fine detail | Moderate to good if quality film is used | Trend driven, seasonal graphics |

| Screen print or sublimation with integrated logo | Nylon and polyester webbing | All over art with embedded branding | Moderate outdoors, better on leashes than buckles | Playful, colorful collections |

| Metal logo plate or charm | Leather, faux leather, thick nylon webbing, harness chest plates | Solid and classic | Very good if corrosion safe | Premium classic, heritage |

| Leather or faux leather label | Fabric harness panels, nylon webbing overlays | Warm and tactile | Good if sealed edges | Boutique, natural, lifestyle |

| Hook and loop patch system | Fabric harness panels, tactical styles | Modular and interactive | Very good when stitched well | Working dog, training, streetwear |

| Laser engraving on hardware | Metal buckles, D rings, snap hooks | Precise and permanent | Excellent | Premium technical, understated |

| Molded logo on plastic buckles | Acetal or nylon buckles and sliders | Clean integrated detail | Excellent | Mass premium, consistent brand sets |

Woven Labels

Woven tabs are probably the quietest way to show identity, yet also one of the most common. A simple label stitched to nylon webbing says, “this is who we are” without altering the product’s look or feel. They’re lightweight, legible, and cost-friendly, which explains their dominance in supermarkets and online channels. They won’t make a collar look high-end, but for practical everyday gear, they work exactly as intended.

Embroidery

Embroidery has a crafted charm. On padded collars or fabric harness panels, it adds depth you can actually feel with your hand. It’s not meant for thin webbing—it needs space—but on wide areas it communicates quality and tradition. Embroidery belongs to brands that want customers to sense the care stitched into every detail.

Silicone or Rubber Patches

Bold, colorful, and three-dimensional, rubber patches are the face of sporty pet products today. They bend with the collar, shrug off mud, and wipe clean in seconds. Paired with PVC webbing, they almost feel like a natural match—both tough, waterproof, and performance-driven. If your brand identity is modern, energetic, and outdoor-oriented, this is where your logo will shine.

Embossing and Debossing

Embossing is the art of understatement. Instead of adding a layer, it presses the brand into the material itself. On PVC-coated webbing or leather, the result is subtle but permanent—no peeling, no fading, no extra weight. It’s a technique that says: “we don’t need to shout, because we know our worth.” Perfect for minimalist or luxury collections.

Heat Transfer Printing

Heat transfer makes it possible to add vivid color, gradients, or even intricate designs. It’s quick, flexible, and works especially well on flat nylon or fabric harness shells. Of course, longevity depends on quality: a cheap film won’t last through washing and abrasion. For trend-focused or seasonal product lines, it allows rapid creative expression.

Screen Printing and Sublimation

When the whole product is about graphics, printing is the obvious choice. Sublimation on polyester webbing gives bright and lasting patterns, while screen printing suits larger fabric surfaces. The key is planning—logos integrated into prints need contrast so they remain visible even from a distance. Playful brands that thrive on colors and themes often rely on this approach.

Metal Plates and Charms

Few things signal “premium” like metal. A polished plate riveted to a leather collar or a charm hanging from a harness chest plate instantly elevates the piece. Done properly, with smooth edges and anti-corrosion coating, it can last as long as the product itself. Metal logos speak to heritage and timelessness—perfect for collections that want to feel substantial.

Leather Labels

A stitched leather or faux leather tab changes the mood of a product completely. Suddenly, a nylon harness looks boutique, warm, and lifestyle-driven. It’s not the most waterproof option, but with proper sealing, it lasts reasonably well. For eco-inspired or cozy, design-led brands, leather labels are a natural fit.

Hook-and-Loop Patches

More interactive than any other method, hook-and-loop patches give flexibility. Owners can swap out badges for reflective tiles, training cues, or even holiday themes. It’s branding that adapts and becomes part of the user’s story. That’s why it’s a favorite among tactical and training harnesses, and increasingly among streetwear-inspired collections.

Laser Engraving

Some brands don’t want the logo on the fabric at all—they want it in the hardware. Etched into a buckle or a D-ring, the logo is precise, permanent, and discreet. This technique suits brands that value technical refinement, where every detail is controlled down to the hardware itself.

Molded Logos on Buckles

For mass production with consistent identity, molded logos on plastic buckles or sliders are highly effective. The logo becomes part of the tooling itself—clean, durable, and repeatable across colors and product families. It doesn’t stand out loudly, but it keeps a line cohesive.

Choosing by Material

- PVC webbing loves embossing, rubber patches, and engraved hardware. Avoid thin surface prints that scratch too easily.

- Nylon and polyester webbing work best with woven labels, silicone patches, transfers, and sublimation. Embroidery is possible with backing tape.

- Leather and faux leather pair beautifully with embossing, metal plates, and stitched leather tabs. Proper sealing protects them in damp climates.

- Fabric harness panels open the door for embroidery, silicone patches, heat transfers, or removable patches—just reinforce the stitching.

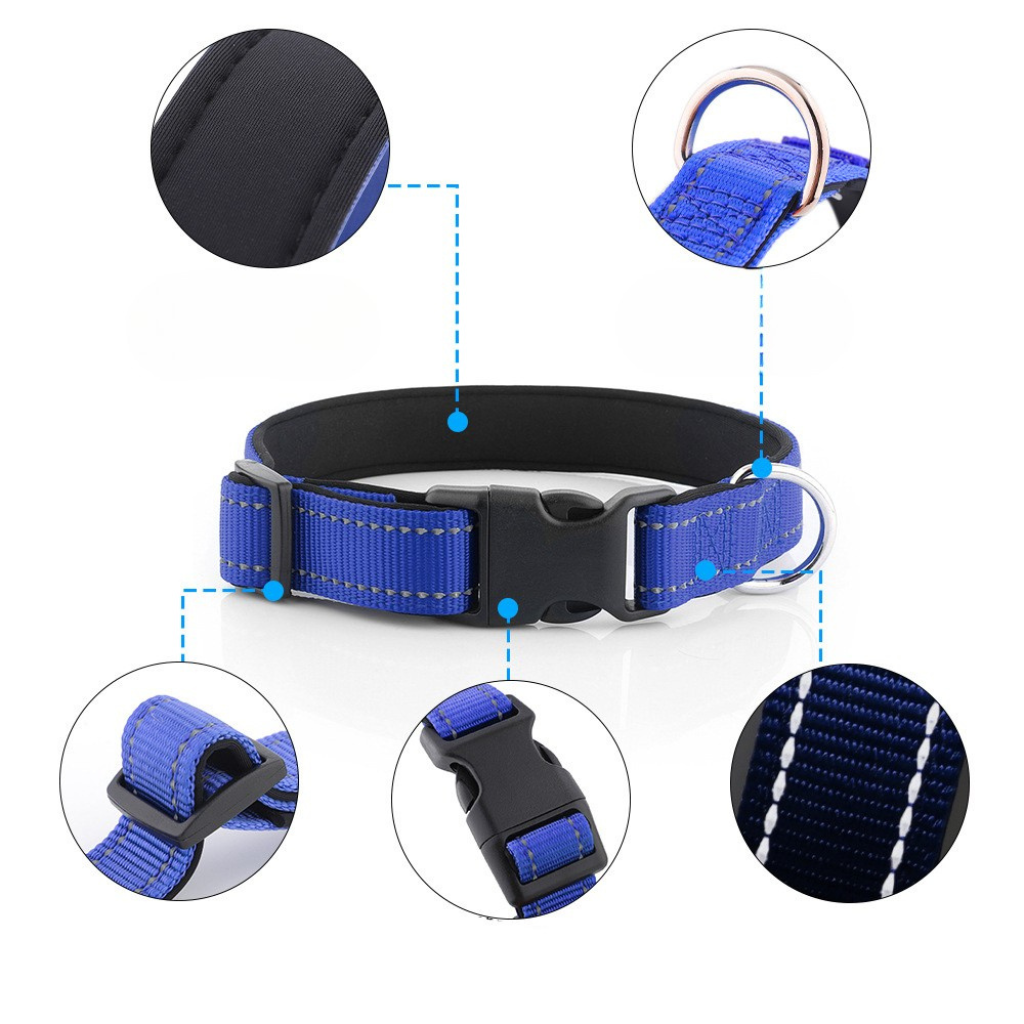

Placement and Scale

- Collars: the side of the neck is the sweet spot. Keep patches low enough to stay visible through fur. Hardware engraving makes a good secondary signature.

- Leashes: the handle for comfort and branding, plus a small logo near the snap for product photography.

- Harnesses: the chest plate for a strong front view, side wings for longer or modular badges. Avoid bulky metal where it can rub.

Care and Durability

Logos live or die by the details. Rounded corners prevent snags, smooth rivets protect the dog’s coat, and UV or salt spray tests ensure colors hold in tough conditions. Choose cleaning methods that don’t cloud PVC or silicone. For brands, these details translate directly into how trustworthy the product feels.

Matching Logos to Brand Personas

- Sport and outdoor: silicone patches, engraved hardware, reflective trims.

- Minimalist premium: embossed PVC or leather, tone-on-tone logos, metal engraving.

- Heritage and classic: embroidery, woven tabs, and polished metal plates.

- Fashion and seasonal: heat transfer prints, sublimated graphics, removable badges.

A Simple Path to Decide

- Start with your material and the main use case.

- Pick two techniques that suit both.

- Place one bold logo for visibility and one subtle mark for close-up detail.

- Test comfort and snag resistance in real wear.

- Standardize colors and textures to unify the line.

Building a Cohesive Branding Set

The best collections don’t rely on just one logo. They layer them. An embossed mark on PVC webbing paired with an engraved buckle. A woven tab on a harness paired with a silicone patch on the side. When packaging, hang tags, and on-product branding all share a language, customers immediately sense consistency and professionalism.

One Response